Rubber O Rings and Seals

The rings and seals we manufacture have gained huge accolades in the market for their host of qualitative features such as durability, sturdiness and dimensionally accurate. These are fabricated using premium quality material sourced from reliable vendors. Available in different shapes and sizes, these can also be customized as per the specification detailed by the clients.

Rubber O Rings

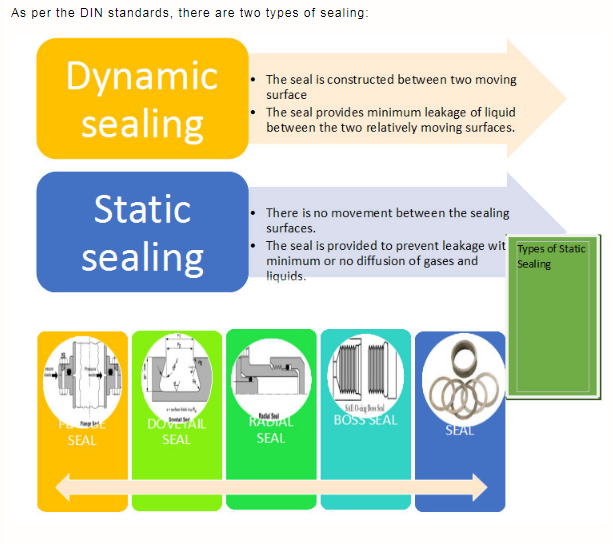

Orings are geometrical elastomer products which have extremely wide range of applications at a very affordable low pricing. They are most used to provide easy, fast and efficient sealing in various industrial or domestic settings. The elastomers used for manufacture of the Oring have extremely high viscosity that transmits in all directions when necessary force and pressure is applied. The Oring is a form of a barrier which prevents leaks from cross sections and joints between two sealing surfaces.

Rubber O Rings

The rubber orings can be used for a variety of applications ranging from the industries to the regular day to day needs. The rubber orings are used for sealing purpose, mostly on substances listed below:• Air

• Water

• Lubricating oils

• Hydraulic oils

• Non-flammable hydraulic fluids

• Fuels

• Cooling fluids

• Extinguishing fluids

• Food

• Beverages

• Medical fluids

• Physiological fluids

• Pure or mixed gases

• Pneumatic seals

• Drive belts

DESIGNS OF RUBBER ORING

The Orings are available in various standard sizes and diameters. The cross section of the seal is decided by the type of application and the thickness the sealing material might require.

The most common international standards for 0-Ring dimensions, in addition to ISO 3601/1 are:| USA | SAE AS-568A |

|---|---|

| Great Britain | BS 1806-BS 451,8 |

| Germany | DIN 3771 |

| Sweden | SMS 1586 |

| France | NF T 47 501 |

| Japan | JIS B 2401-77 |

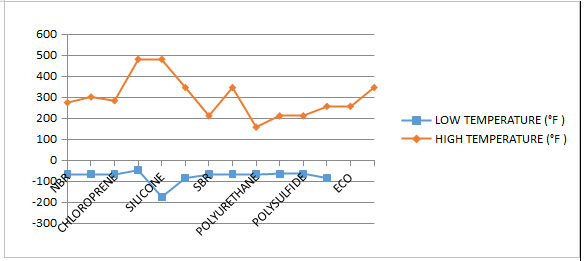

RAW MATTERIAL ELASTOMERS USED FOR RUBBER ORINGS

| TYPE OF ELASTOMER | PROPERTIES |

| NBR | • Stable • Excellent fuel and oil resistance • Good compression set, tear and abrasion resistance • Huge serviceable temperature range |

| EPDM | • Excellent weather resistance • Good low temperature flexibility • Excellent chemical resistance • Great heat resistance • Good resistance to mild acids, alkalis, silicone oils and • greases, ketones and alcohols |

| CHLOROPRENE | • Moderate weather resistance • Versatile • Resistance to petroleum oils • Good compression set and temperature range |

| FKM | • Excellent chemical resistance • Excellent heat resistance • Amazing mechanical properties • Good compression set resistance • Varied temperature range |

| SILICONE | • Wide temperature range at the extremes • Excellent compression set resistance |

| FLUOROSILICONE | • Excellent temperature extremes or range • Good resistance to petroleum oils and fuels • Good compression set resistance |

| SBR | Good resistance to break fluids Good resistance to water |

| POLYACRYLATE | • Excellent resistance to petroleum oil • Excellent weather resistance |

| POLYURETHANE | • Excellent strength and abrasion resistance • Good resistance to petroleum oils • Good weather resistance |

| BUTYL | • Excellent weather resistance • Excellent gas permeation resistance |

| POLYSULFIDE | • Excellent weather resistance to combination of solvents • Excellent weather resistance |

| CSM | • Excellent resistance to weather • Good resistance to heat |

| ECO | • Excellent oil and fuel resistance • Excellent weather resistance • Good low temperature resistance |

| PNF | • Excellent oil and fuel resistance • Wide range of temperature extremes • Good compression set resistance |