Rubber elbows

Rubber elbows are rubber molded sleeves which are used inside or outside machine parts or pipes to reduce resistance and air intake. They are set at different angles and direction to suit the need of the buyer. They are often an essential accessory for cramped up spaces or for connecting pipes from one place to another. Often due to limitation of space the pipes are made to take turns or bends which can only be joined with the help of a rubber elbow in order to prevent breakage or leakage.

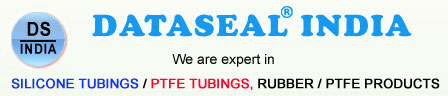

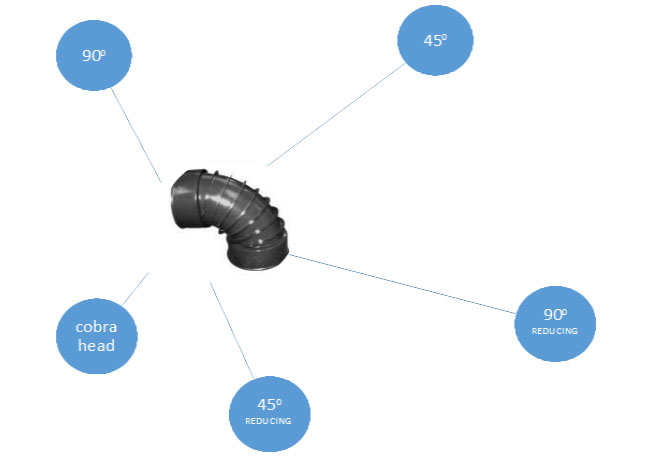

Although, flexible rubber elbows could be designed to suit the needs of the buyer but the original manufacture is of stiff elbows as they last long and suffer less wear and tear. They can be also removed manually in case of repairing or replacement of the elbow or pipes. The typical elbows are inclined at an angle of 45 and 90. However, there are multiple other designs to look from.

These elbows function well and show extreme resistance towards environment (ozone, air and weather), grease, oil, heat, punctures and pressure.

PICTORIAL VIEW OF THE RUBBER ELBOWS

The basic view of the 90 and 45 elbows are:

MATERIAL USED FOR RUBBER ELBOWS

The rubber elbows come in various diameters to suit a variety of applications such as hoses or pipes. The shape can also be customized as per the needs or specialty of the pipe such as cubical connectors.

The rubber elbows are mostly made of natural rubber and silicone depending on the area of application. The silicone elbows are more ideally suited for high pressure and temperature applications where there might be compression of air involved. However, the natural rubber type is suitable for rest of the other applications.

Although, elbows are strong but signs of wear and tear should be duly noted in order to change them before time. These signs could be softness, holes, cracking and crumbling of the rubber elbow.

APPLICATIONS OF RUBBER ELBOWS

Although there are innumerous applications of the rubber elbow but some of the most common ones that we see everyday are:

• They are used as joints for pipelines including metal or plastic pipes.

• They can be used with rubber hoses for connection purposes.

• They are used in plumbing.

• They are used in the various industries to connect the pipes.

• They are used for slurry handling for pump suction and discharge.

• Oil suction and discharge applications where there is thermal movement in the pipelines.

TEMPERATURE RANGE OF THE RUBBER ELBOWS

The average temperature range within which these elbows function efficiently is -400 to 2500 F. however, special designs can be made for higher temperature lasting up till 3000 F.