Rubber Expansion Joints

The rubber expansion joints are designed for piping systems to absorb or contract to compensate and dampen the excessive force within the pipelines. They are extremely reliable and efficient even in operations in nuclear power plants which have extremely high pressure and temperature conditions. They are made of high quality rubber to improve efficiency in the engineered processes and have multiple applications in the various chemical and environmental industries.

PROPERTIES OF RUBBER EXPANSION JOINTS

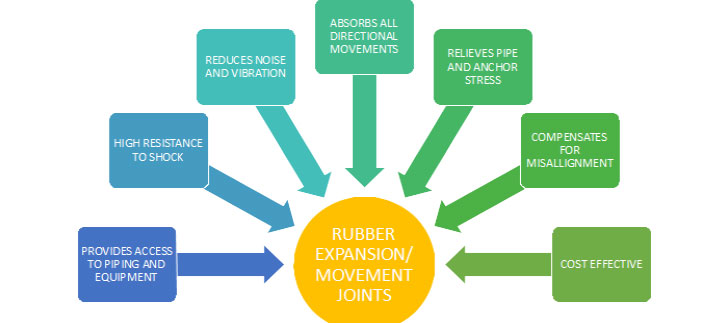

The rubber has excellent properties which enables the extensive use of rubber expansion joints in various industries. Some of the properties of rubber expansion joints are:

• ABSORBS ALL DIRECTIONAL MOVEMENTS

The joints enable superior quality axial compression, axial extension and lateral deflection. Also, the joints provide angular and torsion direction along with many other advantages.

• REDUCES NOISE AND VIBRATIONS

The joints dampen and insulate the excessive noise and vibrations caused by the mechanical equipment.

• HIGH RESISTANCE TO SHOCKRELIEVES PIPE AND ANCHOR STRESS

They are ideally suited for earthquakes and other ground movement activities such as explosion.

• COMPENSATES FOR MISALLIGNMENT

They compensate for pipe misalignment until it can be corrected.

• PROVIDING ACCESS TO PIPING AND EQUIPMENT

The piping and equipment can be reached by just removing the joints which can be done with great ease.

• COST EFFECTIVE

They are much cheaper than the old traditional metal joints which required higher maintenance as well.

TYPES OF RUBBER EXPANSION JOINTS

The rubber expansion joints are primarily of two types:

MATERIALS (TYPES OF RUBBER) USED FOR PRODUCTION OF EXPANSION JOINTS

ESSENTIAL PROPERTIES OF VARIOUS RUBBERS ENABLING THE USE IN RUBBER EXPANSION JOINT MANUFACTURING

| TYPE | COLOR | PROPERTY |

| NEOPRENE | Black | Excellent weather, oil and gasoline resistance. |

| EPDM | Red | Amazing ozone, sunlight, chemical, water and compressed air resistance. Great electrical insulation. Unsuitable for uses with oil, greases and gasoline. |

| NBR | Yellow | It has an excellent resistance against oil, gasoline, gases, solvent, greases, and abrasion. |

| HYPALON CSM | Green | Outstanding chemical and environmental resistance. |

| BUTYLL IIR | Blue | The rubber has amazing resistance towards chemicals, environment and compressed air. |

| VITON FPM | Purple | Highly suitable for oil, gasoline and solvents only. |

| PTFE | White | Remarkable resistance to all media except some chemicals at certain conditions. |

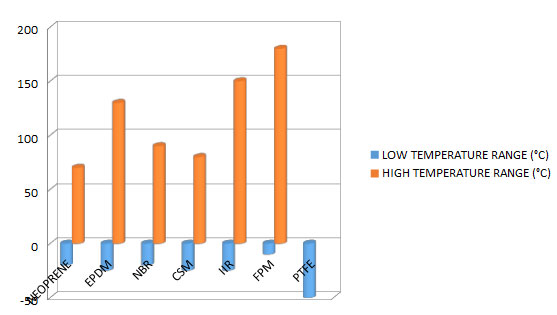

TEMPERATURE RANGE OFFERED BY THE VARIOUS RUBBER EXPANSION JOINTS

The rubber expansion joints we manufacture are acknowledged for their host of qualitative features such as durability, strength and dimensional accuracy. These are manufactured using qualitative material sourced from trusted vendors. These joints finds extensive application in various industries and are offered as per the requirement of the clients.

Rectangular Expansion Joints

We offer a wide assortment of rectangular expansion joints that are widely used in all piping systems to offer relief from stresses by thermal expansion, contraction and vibration. These joints are offered in various sizes ranging from 1” (25mm) NB to 60” (1500mm) mm. The entire range is available in different types such as standard single, multiple arches with or without retaining metallic rings. The joints are fabricated of high tensile rubber reinforced with nylon, rayon, tyre cord, wire mesh, depending on applications and pressure rating. The range of rubber comprises nitrile, neoprene, natural, EPDM, butyl, hypalon and Viton.

Dataseal India - Rubber Expansion Joints Sizes - Download Catalogue